When it comes to choosing the best floor coating for your garage or workspace, you might find yourself stuck between Polycuramine and Epoxy. Both promise durability and a fresh look, but which one truly meets your needs?

You want a floor that not only looks great but stands up to daily wear, resists stains, and lasts for years without peeling or fading. You’ll discover the key differences, benefits, and drawbacks of Polycuramine versus Epoxy coatings. By the end, you’ll feel confident in making the right choice for your space—saving time, money, and frustration.

Ready to find out which floor coating is the perfect match for your project? Let’s dive in.

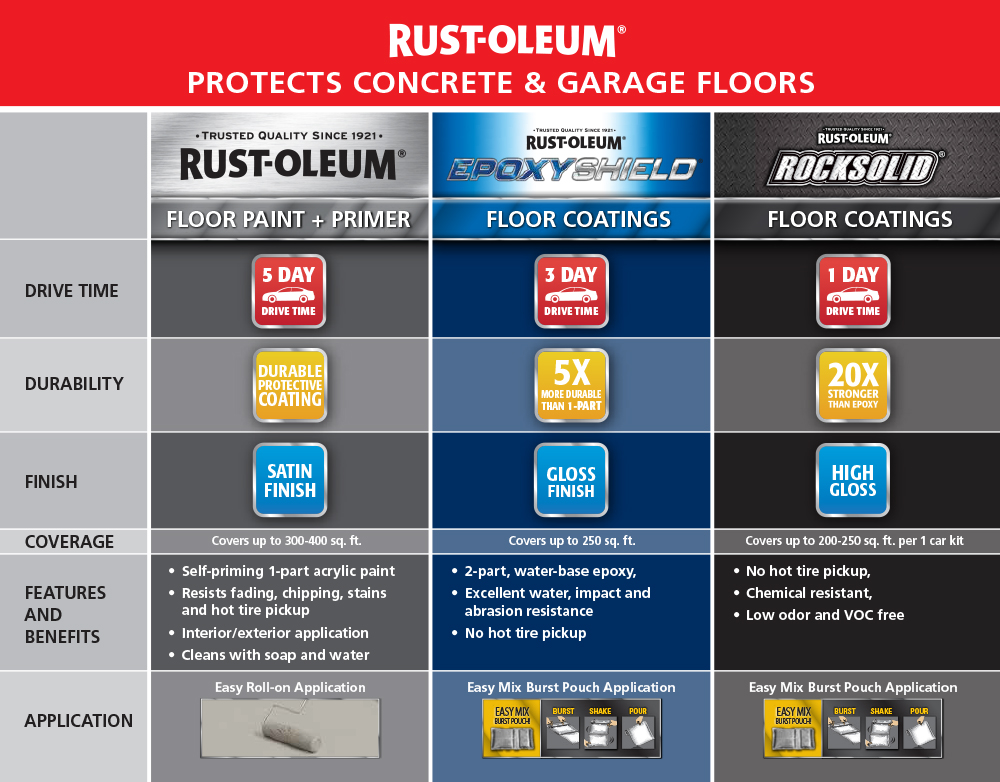

Credit: www.rustoleum.com

Material Composition

Understanding the material composition of Polycuramine and Epoxy helps to grasp their performance differences. Both materials serve as protective coatings but differ in their chemical makeup. This difference influences their strength, durability, and application process.

Exploring the chemical structure and components of each material provides insight into why they behave uniquely under various conditions.

Chemical Structure Of Polycuramine

Polycuramine is a hybrid polymer combining polyurea and polyaspartic chemistries. It contains isocyanate groups that react quickly with amines. This reaction forms a tough, flexible network. The molecular chain has segments that resist chemicals and abrasion. Polycuramine cures fast, often within hours. Its structure allows it to bond tightly with concrete surfaces. This makes it highly durable and resistant to wear.

Epoxy Resin Components

Epoxy consists of two main parts: resin and hardener. The resin is a viscous liquid made from epoxide groups. The hardener contains amine or anhydride compounds. When mixed, they undergo a chemical reaction called curing. This forms a rigid, cross-linked polymer. Epoxy bonds well to many surfaces but cures slower than polycuramine. Its structure is dense, which provides strong adhesion and chemical resistance. However, it can be brittle and less flexible.

Strength Comparison

Comparing the strength of polycuramine and epoxy reveals important differences. Both materials offer solid protection for surfaces. Strength impacts how long coatings last under stress. Understanding their tensile, impact, scratch, and abrasion resistance helps choose the right product.

Tensile And Impact Resistance

Polycuramine shows high tensile strength, making it tough against pulling forces. It stretches slightly before breaking, which adds durability. Epoxy also has good tensile strength but tends to be more brittle. Polycuramine absorbs shocks better, reducing cracks from impacts. This makes it ideal for floors exposed to heavy loads or sudden hits. Epoxy can crack under strong impact, limiting its use in rough conditions.

Scratch And Abrasion Durability

Polycuramine resists scratches and abrasion very well. It maintains a smooth, clean surface even after heavy use. Epoxy is harder but more prone to surface scratches. Over time, epoxy coatings can wear down and show marks. Polycuramine’s flexibility helps it avoid damage from friction and scrapes. This feature suits garages, warehouses, and busy areas needing long-lasting protection.

Durability Factors

Durability plays a key role in choosing between Polycuramine and Epoxy coatings. Both materials offer strong protection, but their performance varies under different conditions. Understanding how each coating handles sunlight, water, and chemicals helps in making the right choice.

Uv Resistance And Color Stability

Polycuramine resists UV rays better than epoxy. It keeps its color vibrant and does not yellow under sunlight. Epoxy tends to fade and turn yellow when exposed to UV light. This makes Polycuramine ideal for outdoor spaces or areas with strong sunlight. Color stability means less maintenance and longer-lasting beauty.

Water And Chemical Resistance

Polycuramine repels water effectively, preventing damage from moisture. It handles chemicals like oils and cleaners with ease. Epoxy also offers good resistance but can absorb some water over time. Chemical spills may cause stains or dullness on epoxy surfaces. Polycuramine’s superior resistance reduces the risk of cracks and peeling.

Application Process

The application process for Polycuramine and Epoxy differs in key steps. Understanding these differences helps achieve the best results. Each material requires specific preparation and curing conditions. These impact the durability and appearance of the finished surface.

Surface Preparation Requirements

Both Polycuramine and Epoxy need clean, dry surfaces. Remove dirt, oil, and old coatings thoroughly. Concrete must be free of dust and loose particles. Grinding or shot blasting is often necessary to create a rough texture. This helps the coating adhere better. Moisture levels in concrete should be low for Epoxy. Polycuramine is more tolerant of slight moisture but still performs best on dry surfaces.

Curing Time And Conditions

Epoxy typically requires 24 to 72 hours to cure fully. It needs stable temperatures between 60°F and 80°F. High humidity can slow down the curing process. Polycuramine cures much faster, often within a few hours. It tolerates a wider temperature range during application. Polycuramine also resists UV damage and does not yellow in sunlight. Proper ventilation is important for both coatings during curing to ensure safety and best results.

Cost Analysis

Analyzing the costs of Polycuramine versus Epoxy helps make a smart choice. Both materials offer strong floor protection but differ in price. Understanding these differences guides budgeting and project planning.

Initial Material And Installation Costs

Epoxy generally costs less for materials than Polycuramine. Polycuramine products tend to have a higher price due to advanced formulas. Installation for Polycuramine often requires professional skills, raising labor costs. Epoxy can be easier for DIY installation, saving money on labor. Polycuramine cures faster, which may reduce overall project time and labor expenses. The cost gap depends on project size and location.

Long-term Maintenance Expenses

Polycuramine offers superior durability, reducing repair needs over time. Its resistance to chemicals and UV light lowers maintenance frequency. Epoxy floors may require more frequent recoating and repairs due to wear. Maintenance for epoxy can include cleaning and touch-ups to maintain appearance. Polycuramine’s toughness can save money by extending the floor’s lifespan. Considering these factors helps balance upfront costs with future expenses.

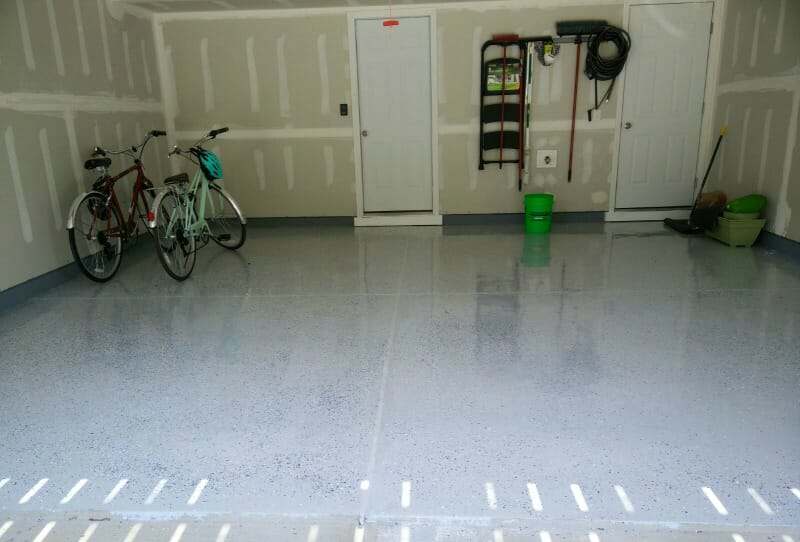

Credit: allgaragefloors.com

Environmental Impact

The environmental impact of Polycuramine and Epoxy plays a key role in choosing the right coating. Understanding their effects helps make safer and greener decisions. Both materials have different footprints in terms of air quality and resource use.

This section breaks down their environmental aspects, focusing on VOC emissions and sustainability. It highlights how these coatings affect health and the planet.

Voc Emissions And Safety

Volatile Organic Compounds (VOCs) are harmful chemicals released during application. Epoxy coatings tend to emit higher VOC levels. These compounds can cause respiratory issues and pollution.

Polycuramine usually has lower VOC emissions, making it safer for indoor use. Reduced fumes improve air quality and lower health risks. Using low-VOC products protects workers and occupants.

Sustainability Considerations

Epoxy often relies on petroleum-based ingredients, which are non-renewable. Its production can involve energy-intensive processes. Disposal of epoxy waste requires care to avoid environmental damage.

Polycuramine formulations may include more eco-friendly components. Some versions offer longer durability, reducing the need for frequent reapplication. This longevity lessens material waste and resource use.

Choosing coatings with sustainable certifications supports environmental protection. Proper handling and disposal of both products are essential to minimize impact.

Common Uses

Both polycuramine and epoxy have specific strengths that suit different needs. Understanding their common uses helps in choosing the right coating. Each material performs best in certain environments and applications.

Residential Applications

Polycuramine is popular for garage floors and basements. It offers strong resistance to stains and chemicals. This makes it ideal for areas prone to spills. Epoxy also works well in homes. It creates a smooth, shiny surface that looks good in kitchens and laundry rooms. Both coatings protect concrete floors from wear and tear. Polycuramine dries faster, so homeowners can use the space sooner. Epoxy is often chosen for its affordability and ease of application. Each material improves the durability and appearance of residential floors.

Commercial And Industrial Uses

Polycuramine suits heavy-duty commercial spaces. It handles high traffic and resists impact well. Warehouses and workshops benefit from its fast curing time. Epoxy is widely used in industrial settings too. It provides excellent adhesion and chemical resistance. Factories and retail stores often use epoxy coatings. Both materials protect floors from damage and reduce maintenance costs. Polycuramine’s flexibility helps in environments with temperature changes. Epoxy remains a strong choice for budget-conscious projects. These coatings extend the life of floors in demanding places.

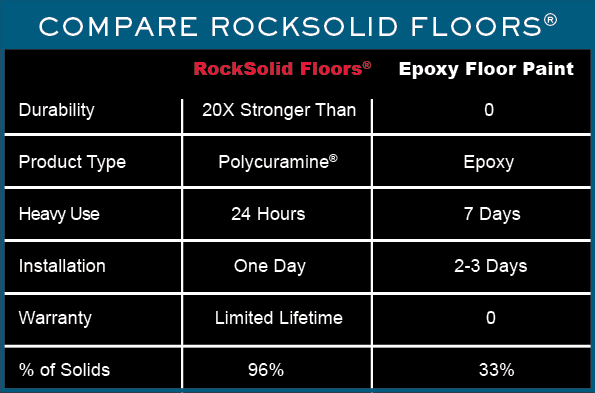

Credit: s189356221.onlinehome.us

User Experience

User experience plays a key role in choosing between Polycuramine and epoxy coatings. Understanding how each product feels during application and after installation helps homeowners and professionals decide which fits their needs better.

Ease Of Diy Application

Polycuramine is designed for simple DIY use. It mixes easily and spreads smoothly on floors. The quick drying time means less waiting before walking on the surface. This coating resists bubbles and uneven spots, making it easier to get a clean finish. Epoxy usually requires more careful mixing and timing. It takes longer to cure and needs a controlled environment to avoid issues. For beginners, epoxy can be tricky and may lead to mistakes like peeling or discoloration.

Professional Installation Insights

Professionals appreciate Polycuramine for its fast cure and strong adhesion. It performs well under heavy traffic and resists chemicals effectively. Experts find it more forgiving during application, reducing costly errors. Epoxy remains popular due to its lower material cost and wide availability. However, it demands precise surface preparation and careful mixing. Pros often spend extra time ensuring proper ventilation and temperature control for epoxy. Both materials require skill, but Polycuramine often cuts down labor time and cleanup.

Frequently Asked Questions

What Is Better, Epoxy Or Polycuramine?

Polycuramine offers faster curing, superior durability, and water resistance. Epoxy is more affordable and easier for DIY projects. Choose polycuramine for longevity; select epoxy for budget-friendly, simpler applications.

Is Polycuramine Waterproof?

Polycuramine is waterproof and repels water effectively. Its hydrophobic nature protects surfaces from moisture damage.

Is Polyaspartic Really Better Than Epoxy?

Polyaspartic outperforms epoxy with faster curing, superior durability, and UV resistance. It costs more but suits outdoor, high-traffic areas better. Epoxy is cheaper, easier for DIY, and works well indoors without sunlight exposure. Choose based on budget, project type, and durability needs.

What Is The Most Durable Garage Floor Coating?

Polyaspartic coatings offer the most durable garage floor protection. They resist scratches, UV damage, and hot tire pickup better than epoxy. Polyaspartic cures quickly and lasts longer, making it ideal for heavy use and outdoor exposure.

What Is The Main Difference Between Polycuramine And Epoxy?

Polycuramine cures faster and is more flexible, while epoxy is harder but takes longer to dry.

Conclusion

Choosing between polycuramine and epoxy depends on your needs. Polycuramine offers fast curing and strong durability. Epoxy is budget-friendly and easier for beginners. Both protect floors well but differ in lifespan and resistance. Consider your budget, project size, and environment before deciding.

Each coating suits different situations and preferences. Quality preparation and application matter most for a lasting finish. Take time to weigh pros and cons carefully. Your choice will affect floor performance and appearance.