When you face cracks or leaks in your concrete, choosing the right repair material can make all the difference. You might have heard about hydraulic cement and epoxy as popular options, but which one is truly the best for your needs?

Understanding how each works and where they shine can save you time, money, and frustration. You’ll discover the key differences between hydraulic cement and epoxy — from their durability to how they handle water leaks — so you can make a confident choice for your concrete repairs.

Keep reading to learn which solution will give your project the lasting strength it deserves.

Hydraulic Cement Basics

Hydraulic cement is a key material in construction and repair projects. It hardens quickly and stops water fast. Many builders use it to patch leaks and cracks. Understanding its basics helps to know when to choose it over epoxy.

This section explains what hydraulic cement is made of, how it sets, its common uses, and its limits. Each part gives clear facts to guide your decision.

Composition And Setting Process

Hydraulic cement contains cement, sand, and special chemicals. These chemicals react with water to harden quickly. This process is called hydration. It forms a strong, water-resistant material in minutes. Unlike regular cement, hydraulic cement sets even underwater.

Common Uses In Construction

Hydraulic cement works well for stopping active water leaks. It seals cracks in concrete walls and floors. Workers use it to patch holes in foundations and basements. Its fast setting time makes it ideal for emergency repairs. It also fills joints and gaps to prevent water flow.

Limitations And Challenges

Hydraulic cement is rigid and cannot move with shifting structures. This can cause new cracks to form. It is not a permanent fix for structural damage. It only stops leaks temporarily. The bond to old concrete can weaken over time. It does not solve the root cause of leaks, like pressure or movement.

Credit: www.therealsealllc.com

Epoxy Fundamentals

Epoxy is a strong adhesive used in many concrete repairs. It bonds tightly to surfaces and seals cracks effectively. This material is popular because it lasts long and withstands harsh conditions.

Epoxy comes as two parts: resin and hardener. When mixed, they create a tough plastic that sticks well to concrete. This makes epoxy ideal for fixing and protecting concrete structures.

Chemical Properties

Epoxy is a thermosetting polymer. It cures through a chemical reaction between resin and hardener. This reaction forms a rigid, durable material.

It resists water, chemicals, and heat. Epoxy does not shrink much when it hardens. This keeps cracks sealed tightly and prevents leaks.

Applications In Concrete Repair

Epoxy is used to fill cracks and bond broken concrete pieces. It seals joints to stop water entry. Epoxy injection repairs structural cracks inside concrete walls and slabs.

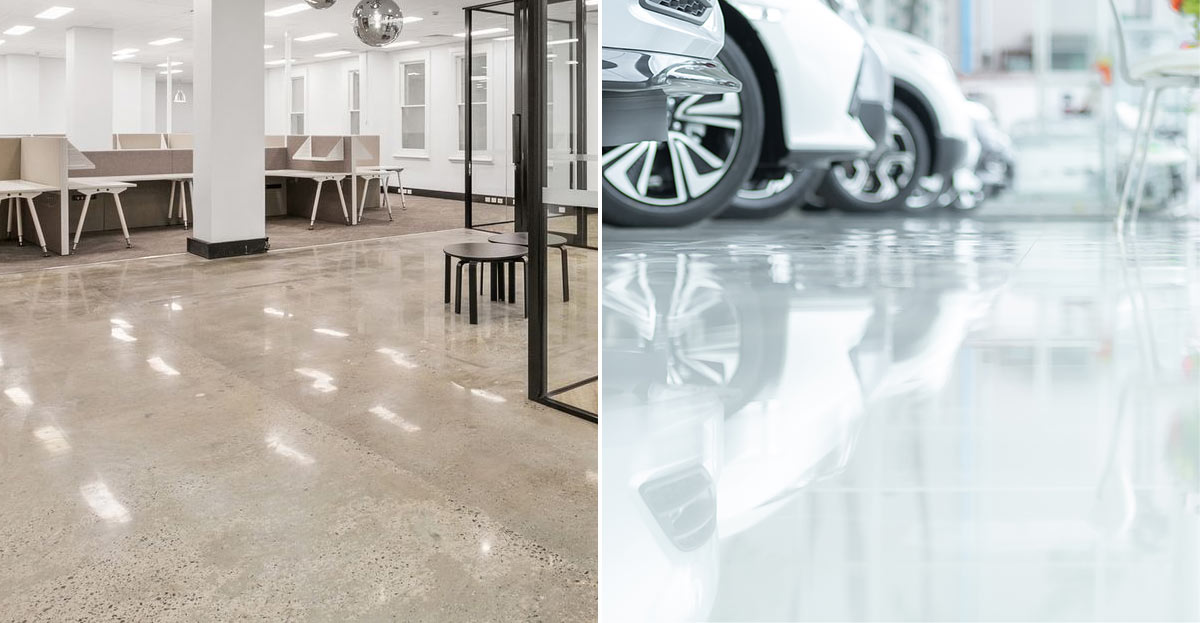

It also protects surfaces from wear and chemical damage. Epoxy coatings improve concrete durability in industrial and commercial settings.

Advantages Over Other Materials

Epoxy bonds stronger than many other repair materials. It is flexible enough to handle slight movements in concrete. This reduces the chance of new cracks forming.

Epoxy lasts longer and resists moisture better than hydraulic cement. It creates a permanent seal that stops leaks effectively. Its chemical resistance protects concrete from harsh environments.

Strength Comparison

Comparing the strength of hydraulic cement and epoxy helps choose the right material. Both serve different purposes in concrete repair and construction. Strength is key in deciding which one fits your project needs.

This section breaks down their strength in three important areas: load bearing, adhesion, and resistance to cracking.

Load Bearing Capacity

Hydraulic cement has good compressive strength soon after setting. It can bear heavy loads but may weaken over time. Epoxy provides higher load bearing capacity. It hardens into a strong, durable layer. This makes epoxy better for structural repairs that need lasting strength.

Adhesion To Concrete

Hydraulic cement bonds well to concrete surfaces, but its grip can weaken with moisture and time. Epoxy has excellent adhesion and forms a tight bond. It sticks firmly even on rough or damp surfaces. This strong adhesion prevents gaps and improves repair durability.

Resistance To Cracking

Hydraulic cement is rigid and can crack under movement or temperature changes. It does not flex with concrete expansion or contraction. Epoxy is more flexible and resists cracking better. It absorbs stress and adapts to minor shifts in the concrete.

Durability Factors

Durability is a key factor when choosing between hydraulic cement and epoxy. Both materials serve specific purposes in construction and repair. Understanding their durability helps make the right choice for lasting results.

Flexibility And Movement Accommodation

Hydraulic cement hardens quickly but remains rigid. It cannot bend or flex with concrete movement. This rigidity can lead to cracking over time as structures shift or expand. Epoxy, on the other hand, offers better flexibility. It bonds deeply and can absorb some movement without breaking. This makes epoxy a stronger option for areas that experience stress and slight motion.

Waterproofing Capabilities

Hydraulic cement stops water fast by swelling and sealing leaks. It works well for immediate waterproofing. However, it does not create a fully waterproof barrier. Water may seep through small gaps later. Epoxy provides a more complete waterproof seal. It fills cracks and creates a smooth, impermeable surface. Epoxy is often preferred for long-term water resistance in wet environments.

Longevity Under Stress

Hydraulic cement may degrade under constant stress or pressure. Its brittle nature causes it to crack and fail over time. Epoxy withstands stress better due to its strong adhesive properties. It resists chemicals, moisture, and pressure without losing bond strength. Epoxy repairs tend to last longer and maintain integrity in harsh conditions.

Repair Scenarios

Repair scenarios for concrete cracks and leaks vary widely. Choosing the right material depends on the problem type and repair goals. Hydraulic cement and epoxy serve different purposes in these repairs. Understanding their strengths helps in selecting the best option for each case.

Stopping Active Leaks

Hydraulic cement works well to stop active water leaks fast. It expands as it sets, blocking water flow immediately. This makes it ideal for emergency leak control. Epoxy, however, requires dry surfaces and longer curing times. It is not suitable for stopping active leaks quickly.

Structural Crack Sealing

Epoxy is best for sealing structural cracks. It bonds strongly with concrete and restores strength. Epoxy fills cracks deeply and prevents further damage. Hydraulic cement is rigid and can crack again under stress. It offers only a temporary fix for structural issues.

Surface Patching

Hydraulic cement is effective for small surface patches. It sets fast and can fill holes or voids on concrete surfaces. Epoxy also works for surface repairs but is more expensive and requires careful preparation. For quick, shallow repairs, hydraulic cement is often preferred.

Application Techniques

Understanding the application techniques of hydraulic cement and epoxy is essential for effective repairs. Each material requires specific preparation and methods to perform well. Knowing these steps helps ensure durability and proper sealing.

Preparation And Surface Treatment

Start by cleaning the surface thoroughly. Remove dust, dirt, and loose particles. For hydraulic cement, dampen the surface but avoid standing water. Epoxy needs a dry and clean area. Roughen smooth surfaces to improve adhesion. Proper surface treatment prevents failures and improves bonding.

Mixing And Application Methods

Hydraulic cement usually comes as a powder. Mix it with water to a thick, putty-like consistency. Apply quickly, as it sets fast. Use a trowel to press it into cracks or holes. Epoxy comes as two parts: resin and hardener. Mix them according to instructions. Apply with a brush, roller, or injection tools. Epoxy spreads smoothly and fills gaps deeply.

Curing Time And Conditions

Hydraulic cement cures fast, often within 10 to 20 minutes. It gains strength quickly but needs moisture to cure properly. Keep the area damp for better results. Epoxy takes longer to cure, from several hours to days. It cures best at room temperature with low humidity. Avoid disturbing the repair during this time to ensure strong bonding.

Cost And Availability

Understanding the cost and availability of hydraulic cement and epoxy is important for any repair project. These factors impact your budget and timeline. This section breaks down the key points to help you decide.

Material Costs

Hydraulic cement usually costs less than epoxy. It is a basic material made for quick repairs. Epoxy is more expensive because it offers stronger, long-lasting bonds. The price difference can affect the total repair cost. Choose based on your budget and repair needs.

Ease Of Access In Austin, Texas

Hydraulic cement is widely available in Austin at most hardware stores. It is easy to find and buy in small or large quantities. Epoxy products are less common and might require a specialty supplier. Some types of epoxy need ordering online or from specialty stores. Plan ahead to avoid delays in your repair work.

Labor And Equipment Needs

Hydraulic cement is simpler to apply. It usually needs only basic tools and less time. Epoxy requires more skill to mix and apply correctly. Specialized equipment may be necessary for some epoxy types. Labor costs can be higher with epoxy due to the complexity and safety measures. Consider labor and tool availability when choosing a material.

Environmental Impact

The environmental impact of hydraulic cement and epoxy plays a key role in their selection for construction projects. Both materials affect the environment differently during production, use, and disposal. Understanding these differences helps choose the best option for eco-friendly building and repair.

Sustainability Considerations

Hydraulic cement is made from natural materials like limestone and clay. Its production releases significant carbon dioxide, contributing to greenhouse gases. Epoxy, a synthetic resin, requires petroleum-based chemicals. Its manufacturing uses more energy and non-renewable resources. Hydraulic cement has a higher carbon footprint but uses abundant raw materials. Epoxy offers durability and longer life, which can reduce replacements and waste over time.

Toxicity And Safety

Hydraulic cement is generally less toxic during use. It can cause skin and eye irritation but has no strong fumes. Epoxy contains chemicals that can release harmful vapors during mixing and curing. Proper ventilation and protective gear are essential. Epoxy may cause allergic reactions in some people. Both materials need careful handling to protect workers and occupants.

Disposal And Cleanup

Hydraulic cement waste is mostly inert once hardened and can be disposed of as construction debris. Cleanup requires water and scrubbing but poses low environmental risk. Epoxy waste is hazardous if not fully cured and must be handled according to hazardous waste rules. Cleanup needs solvents that may be toxic and require special disposal. Improper disposal of epoxy can harm soil and water quality.

Choosing The Right Material

Choosing the right material for concrete repair affects the durability and success of your project. Understanding the strengths and limits of hydraulic cement and epoxy helps make the best choice. Each material suits different needs and repair types. Clear insight avoids costly mistakes and repeat repairs.

Assessing Repair Needs

Start by identifying the problem type. Hydraulic cement works well to stop active water leaks fast. It expands as it sets, sealing gaps immediately. Epoxy suits structural cracks needing a strong bond and lasting fix. Epoxy also resists chemicals and can restore concrete strength. Consider the crack size, location, and moisture presence. Small leaks call for hydraulic cement. Larger or load-bearing cracks need epoxy.

Long-term Vs Temporary Fixes

Hydraulic cement offers a quick, temporary solution. It hardens fast but is rigid and can crack again. It does not adapt to concrete movement or address root causes. Use it to stop leaks before a permanent repair. Epoxy provides a durable, flexible repair. It bonds deeply and moves with the concrete. Epoxy fills cracks fully, preventing future leaks. Choose epoxy for long-lasting results and structural safety.

Expert Recommendations

Experts suggest hydraulic cement only for immediate leak control. Afterward, apply epoxy or polyurethane injections for permanent repair. Professionals emphasize surface preparation before using epoxy. Clean, dry cracks improve adhesion and repair strength. For structural cracks, epoxy injection is standard practice. Consult a specialist for large or complex repairs. Proper material choice prevents recurring damage and saves money.

Credit: artofconcrete.com.au

Credit: www.radonseal.com

Frequently Asked Questions

When Not To Use Hydraulic Cement?

Avoid using hydraulic cement for structural cracks, flexible joints, or permanent repairs. It fails with movement and doesn’t fix root causes. Choose epoxy or polyurethane injections for lasting solutions.

Is Hydraulic Cement A Permanent Fix?

No, hydraulic cement provides a temporary fix by stopping active leaks but often cracks again as concrete shifts. For permanent repair, use flexible solutions like epoxy or polyurethane injections that bond and move with the structure.

What Are The Disadvantages Of Hydraulic Cement?

Hydraulic cement is rigid and can crack as concrete moves. It offers only a temporary fix and may not bond well over time. It doesn’t address underlying causes, leading to recurring leaks and damage.

Can You Epoxy Over Hydraulic Cement?

Yes, you can epoxy over hydraulic cement after it fully cures and the surface is clean and dry. Epoxy bonds well to cured hydraulic cement, providing a strong, durable repair. Ensure proper surface preparation for optimal adhesion and long-lasting results.

What Is The Main Difference Between Hydraulic Cement And Epoxy?

Hydraulic cement sets quickly and stops leaks, while epoxy bonds strongly and repairs cracks permanently.

Conclusion

Hydraulic cement and epoxy serve different repair needs in concrete. Hydraulic cement stops active water leaks quickly but stays rigid and temporary. Epoxy bonds strongly and flexes with concrete, making it better for lasting repairs. Choose hydraulic cement for fast, short-term fixes.

Use epoxy for permanent crack repairs and structural strength. Understanding these differences helps pick the right material for your project. Proper repair means fixing the leak and addressing the crack’s root cause. This ensures durable, effective concrete protection over time.