When you’re working on plumbing projects, choosing the right sealant for your pipe threads can make all the difference between a leak-free connection and a costly mess. You’ve probably heard about both pipe dope and Teflon tape, but which one should you use?

Understanding the strengths and weaknesses of each can save you time, money, and frustration. You’ll discover exactly when to reach for pipe dope and when Teflon tape is the better choice. By the end, you’ll feel confident making the right call for your pipes—whether you’re fixing a leaky faucet or installing new plumbing in your home.

Keep reading to find out which option suits your needs best and avoid common mistakes that even experienced DIYers make.

Pipe Dope Basics

Understanding pipe dope is key for successful plumbing projects. It helps seal pipe threads and prevents leaks. Choosing the right type of pipe dope improves joint strength and durability.

This section explains what pipe dope is, the types available, and how it works. Clear knowledge aids in selecting the best sealant for your pipes.

What Is Pipe Dope

Pipe dope is a paste-like substance used on threaded pipe joints. It fills gaps between threads to stop leaks. It also lubricates threads for easier assembly and disassembly. Commonly used in plumbing, gas, and heating systems.

Types Of Pipe Dope

Different types suit various applications and materials. Some are water-resistant, others resist gas or oil. Examples include silicone-based, petroleum-based, and anaerobic compounds. Some pipe dopes contain fillers like clay or graphite for extra sealing.

How Pipe Dope Works

Pipe dope fills tiny gaps between threaded pipes. It hardens or stays flexible to maintain a tight seal. This prevents water, gas, or air from escaping. The paste also lubricates threads to prevent damage during tightening. It creates a strong, leak-proof joint.

Teflon Tape Basics

Teflon tape is a common tool in plumbing. It helps create a tight seal on threaded pipe joints. This section explains the basics of Teflon tape. Understanding its types and how it works will help you choose the right product for your plumbing needs.

What Is Teflon Tape

Teflon tape, also called plumber’s tape, is a thin film made from polytetrafluoroethylene (PTFE). It wraps around pipe threads to prevent leaks. The tape fills gaps between threads and stops water or gas from escaping. It is easy to use and widely available.

Types Of Teflon Tape

Different types of Teflon tape serve different purposes. Standard white tape is for water pipes. Yellow tape is thicker and made for gas lines. Pink tape is for water lines with high pressure. Green tape is for oxygen systems. Choosing the correct type ensures safety and effectiveness.

How Teflon Tape Works

Teflon tape works by sealing the threads of a pipe joint. It fills tiny gaps that could cause leaks. The tape also lubricates threads, making it easier to tighten connections. Proper wrapping of the tape is important. It should cover the threads evenly without overlapping too much.

When To Use Pipe Dope

Choosing between pipe dope and Teflon tape depends on the job requirements. Pipe dope offers a thicker, paste-like sealant. It fills gaps and irregularities in pipe threads. This makes it ideal for certain pipe types and uses. Understanding when to use pipe dope ensures a secure and leak-free connection. Below are key points to consider for pipe dope use.

Suitable Pipe Types

Pipe dope works well with metal pipes. It is best for steel, brass, and iron pipes. The paste seals rough or damaged threads effectively. Avoid using pipe dope on plastic pipes. Plastic threads can be damaged by some compounds. Always check the product label for compatibility.

Ideal Applications

Use pipe dope on high-pressure water lines. It withstands vibration and temperature changes. The compound also works well on outdoor plumbing. Pipe dope prevents corrosion and rust at the joints. It is useful in plumbing repairs and new installations. The paste helps create a strong, lasting seal.

Gas Line Considerations

Pipe dope is suitable for natural gas lines if rated for gas use. Only use pipe dope labeled safe for gas connections. It prevents gas leaks by sealing threaded joints tightly. Avoid using Teflon tape alone on gas lines. Combining pipe dope with tape can provide extra security. Always follow local codes and guidelines for gas piping.

When To Use Teflon Tape

Teflon tape is a popular choice for sealing pipe threads. It prevents leaks by filling gaps between threads. Knowing when to use it ensures a strong, lasting seal. This section explains ideal uses of Teflon tape and how to apply it correctly.

Compatible Threads

Teflon tape works best on tapered threads. These threads tighten as you screw them in. The tape fills small gaps and creates a tight seal. Avoid using it on straight threads or compression fittings. Teflon tape does not seal well on non-threaded connections.

Water Supply Lines

Teflon tape is common on water supply pipes. It resists water and helps prevent leaks. Use it on metal pipes like copper or galvanized steel. Avoid tape on pipes with rubber gaskets or O-rings. Those seals need direct contact to work properly.

Proper Application Techniques

Start by cleaning the threads before applying tape. Wrap the tape clockwise around the threads. Use 2 to 3 layers for best results. Press the tape into the threads as you wrap. Avoid covering the pipe end with tape. This keeps debris from entering the water line.

Common Mistakes With Pipe Dope And Teflon Tape

Using pipe dope and Teflon tape can make plumbing joints secure. Yet, many make common mistakes that cause leaks or damage. Understanding these errors helps avoid costly repairs. Below are frequent missteps to watch out for with these sealing materials.

Applying On Rubber Gaskets Or O-rings

Pipe dope and Teflon tape should not go on rubber gaskets or O-rings. These parts seal by compression, not thread tightness. Adding sealant stops proper compression. This leads to leaks and gasket failure. Keep pipe dope and tape off these seals for best results.

Using On Compression Fittings

Compression fittings rely on a tight metal ring to seal joints. Applying pipe dope or Teflon tape can block this action. The sealant may prevent the ring from gripping the pipe. This causes weak or leaking connections. Avoid using pipe dope or tape on compression fittings.

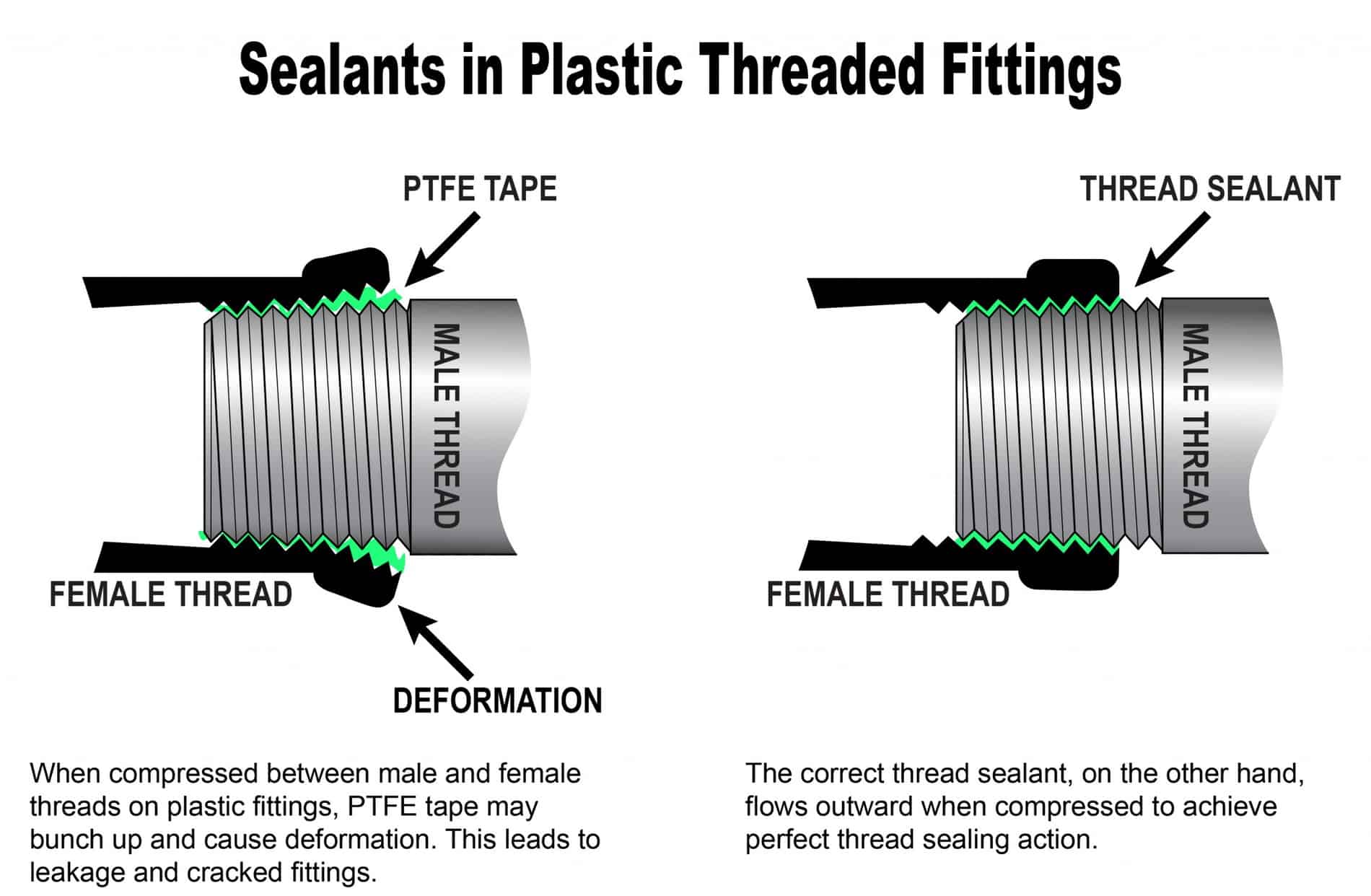

Avoiding On Plastic Pipes

Plastic pipes like PVC or PEX can crack under too much pressure. Pipe dope and Teflon tape increase torque when tightening. This can damage the plastic threads. Use only sealants made for plastic pipes. Or follow manufacturer instructions carefully to protect the pipe.

Comparing Seal Strength And Durability

Seal strength and durability play a vital role in plumbing. Choosing between pipe dope and Teflon tape depends on these factors. This section compares their ability to resist leaks, endure pressure, and withstand harsh conditions. Understanding these points helps pick the right product for your plumbing needs.

Resistance To Leaks

Pipe dope forms a thick, sticky seal around threads. It fills gaps and prevents water or gas from escaping. Teflon tape wraps tightly around threads, creating a thin barrier that blocks leaks. Pipe dope often provides a stronger seal in rough or damaged threads. Teflon tape works well on smooth threads but may slip or tear under stress. Both products reduce leaks but pipe dope tends to seal better on imperfect surfaces.

Longevity Under Pressure

Under high pressure, pipe dope maintains its seal without drying out. It stays flexible and holds threads firmly in place. Teflon tape can compress and lose thickness over time under pressure. This thinning may cause leaks in long-term use. Pipe dope’s paste form adapts to pressure changes better. For pipes with constant or high pressure, pipe dope offers longer-lasting protection than tape.

Temperature And Chemical Resistance

Pipe dope resists a wide range of temperatures and chemicals. It works well in hot water, gas lines, and chemical pipelines. Some pipe dopes are designed for specific chemicals or extreme heat. Teflon tape resists many chemicals but melts or degrades at very high temperatures. It is less suitable for industrial or hot water applications. For tough environments, pipe dope provides more reliable resistance to heat and chemicals.

Ease Of Use And Cleanup

Choosing between pipe dope and Teflon tape involves considering how easy they are to use and clean up. This factor matters for both beginners and experienced plumbers. The right choice can save time and reduce frustration during plumbing projects.

Both materials help seal threaded pipe joints but differ in handling. The ease of application, mess created, and ability to reuse affect the overall user experience.

Application Speed

Teflon tape wraps quickly around pipe threads. It takes only a few seconds to apply. No special tools are needed. Pipe dope requires spreading paste evenly on threads. This step takes more time and care to avoid gaps. Tape often feels faster for simple jobs.

Mess And Cleanup

Teflon tape is clean to use with no sticky residue. Excess tape can be easily trimmed. Pipe dope can be messy to handle. It may stick to hands and tools. Cleanup needs solvents or rags. This can add time and effort after work finishes.

Reusability

Teflon tape is single-use only. Once applied and tightened, it cannot be reused. Pipe dope allows some joints to be disassembled and resealed. This can save money on repeat repairs. However, old dope should be cleaned off before reapplying for a good seal.

Credit: www.fluoramics.com

Environmental And Safety Considerations

Choosing between pipe dope and Teflon tape involves more than just performance. Environmental and safety factors also play a key role in deciding which to use. Understanding the toxicity, handling requirements, disposal methods, and impact on plumbing systems helps ensure safe and eco-friendly plumbing work.

Toxicity And Handling

Pipe dope contains chemicals that can be harmful if inhaled or touched. Always use gloves and work in well-ventilated areas. Avoid direct skin contact to prevent irritation. Teflon tape is generally safer to handle, as it is non-toxic and does not emit fumes. Still, keep it away from children and pets to avoid choking hazards.

Disposal Guidelines

Used pipe dope should be treated as chemical waste. Dispose of it according to local hazardous waste rules. Never pour leftover pipe dope down drains or onto soil. Teflon tape is non-biodegradable but can be disposed of with regular trash. Avoid burning Teflon tape, as it releases harmful gases.

Impact On Plumbing Systems

Pipe dope creates a strong seal but can sometimes clog pipes if over-applied. It may also degrade certain plastics over time. Teflon tape provides a clean seal without residue buildup. It works well on metal pipes but is unsuitable for some plastics and gas lines. Proper selection protects plumbing and prevents leaks.

Expert Tips For Leak-free Seals

Creating leak-free seals in plumbing ensures safety and long-lasting performance. Expert tips help avoid common mistakes with pipe dope and Teflon tape. Proper use and preparation make all the difference. Follow these guidelines to secure tight, durable connections every time.

Combining Tape And Dope

Use Teflon tape first by wrapping it clockwise around threads. Then apply a thin layer of pipe dope over the tape. This combination fills gaps better than using one alone. It prevents leaks and makes disassembly easier later. Avoid thick layers that can cause threads to bind.

Thread Preparation

Clean threads thoroughly before applying sealant. Remove dirt, oil, and old sealant with a brush or cloth. Dry the threads completely to ensure better adhesion. Inspect threads for damage or burrs; smooth out rough spots carefully. Proper prep ensures the tape or dope sticks well and seals tightly.

Tool Recommendations

Use a pipe wrench or adjustable wrench sized to your pipe fittings. Avoid overtightening, which can damage threads or fittings. Wrap Teflon tape with your fingers for control, not scissors or knives. Apply pipe dope with a small brush or your finger for even coverage. Choose tools that provide a secure grip and precision.

Credit: www.sbmar.com

Credit: www.youtube.com

Frequently Asked Questions

Where Not To Use Pipe Dope?

Do not use pipe dope on plastic pipes like PVC or PEX, rubber gasket seals, compression fittings, or certain gas lines. Avoid it where manufacturer instructions prohibit its use.

When Should You Not Use Teflon Tape?

Avoid using Teflon tape on connections with rubber gaskets, O-rings, compression fittings, PVC or PEX pipes, and natural gas lines. It can prevent proper sealing, cause leaks, or damage gas systems. Use pipe dope for gas lines and solvent cement for plastic pipes instead.

Do You Use Pipe Dope Or Teflon Tape On Brass Fittings?

Use pipe dope on brass fittings for gas lines and heavy-duty seals. Teflon tape suits water lines and general plumbing. Avoid tape on fittings with rubber gaskets or compression fittings to prevent leaks. Choose sealant based on fitting type and application for reliable, leak-free connections.

Why Do They Call It Pipe Dope?

They call it pipe dope because it’s a thick, paste-like sealant applied to pipe threads to prevent leaks and ensure tight joints.

What Is The Main Difference Between Pipe Dope And Teflon Tape?

Pipe Dope is a paste sealant, while Teflon Tape is a thin plastic tape used on pipe threads.

Conclusion

Choosing between pipe dope and Teflon tape depends on your project needs. Pipe dope offers a thicker, paste-like seal for metal pipes. Teflon tape is easy to apply and works well for quick fixes. Each has limits; avoid Teflon tape on rubber gaskets or plastic pipes.

Pipe dope can handle certain gas lines better. Understand your pipe type and connection before deciding. Proper use prevents leaks and saves time. Both products serve important roles in plumbing tasks. Select wisely to ensure a strong, lasting seal.